Supplier quality standard specifies certain management system requirements for use in the supplier’s shop and an assurance of quality and continued improvement in the supplier’s performance. Flowmore follows a standard process to develop the necessary competence and to meet the specific quality requirements of our products at the supplier’s end.

|

TEST ACTIVITIES |

REFERENCE CODES USED |

|

Radiography Testing Liquid Penetration Testing Magnetic Particle Testing Ultrasonic Testing |

ASME SEC III-,NB, NC, ND ASME SEC V ASME SEC VIII ASME SEC IX |

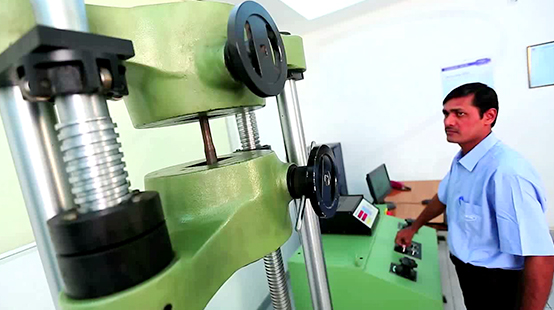

Destructive material tests on samples give additional proof of material quality. Material tests and metallographic examinations are conducted in our own laboratories or in state-accredited testing institutes. These tests are carried out and evaluated exclusively by trained and authorized personnel. The test results are forwarded to the customers in the form of quality certificates.

The measuring instruments used for geometrical checks like gauges, templates and other measuring instruments are subject to a strict, regular and documented calibration process. For this, Flowmore has a well-equipped gauge and instrument room covering a wide range of calibrated instruments to ensure product quality.

We have world class balancing machines made by Schenk with a capacity of up to 5 tonnes. Six machines are available. These machines cover a wide range of sizes and accuracies.

For achieving world class quality levels, special manufacturing and testing facilities have been established as follows

DRY FILM TEST

HOLIDAY TEST

ADHESION TEST

ULTRASONIC TESTING