Overview

Range

Flow: up to 18000 m³/hour

Flow: up to 18000 m³/hour Head: up to 250 m

Head: up to 250 m Sizes : 50 to 1200 mm

Sizes : 50 to 1200 mm

Applications & Services:

Applications & Services:

Power Generations

Power Generations Cooling Water, Circulating Water, Make up Water, Misc. & Auxiliary Services.

Cooling Water, Circulating Water, Make up Water, Misc. & Auxiliary Services. Fire Fighting

Fire Fighting Industrial

Industrial Steel Plants, Sugar Plants, Paper & Textile Mills, Rolling Mills etc.

Steel Plants, Sugar Plants, Paper & Textile Mills, Rolling Mills etc. Fertilizer, Chemical, Refineries, Petrochemicals Plants

Fertilizer, Chemical, Refineries, Petrochemicals Plants Intake Raw Water, Cooling Water, Booster Services etc.

Intake Raw Water, Cooling Water, Booster Services etc. Municipal Water Supply

Municipal Water Supply Clear Water, Raw Water, Waste Water and Auxiliary Services.

Clear Water, Raw Water, Waste Water and Auxiliary Services. Air Conditioning Plants

Air Conditioning Plants Primary & Auxiliary Water

Primary & Auxiliary Water Building Services

Building Services General

General Waste Water Treatment, Mine Dewatering, Lift irrigation, Agriculture, Water Works, Storm Water, sprinkler irrigation, Flood Control etc.

Waste Water Treatment, Mine Dewatering, Lift irrigation, Agriculture, Water Works, Storm Water, sprinkler irrigation, Flood Control etc.

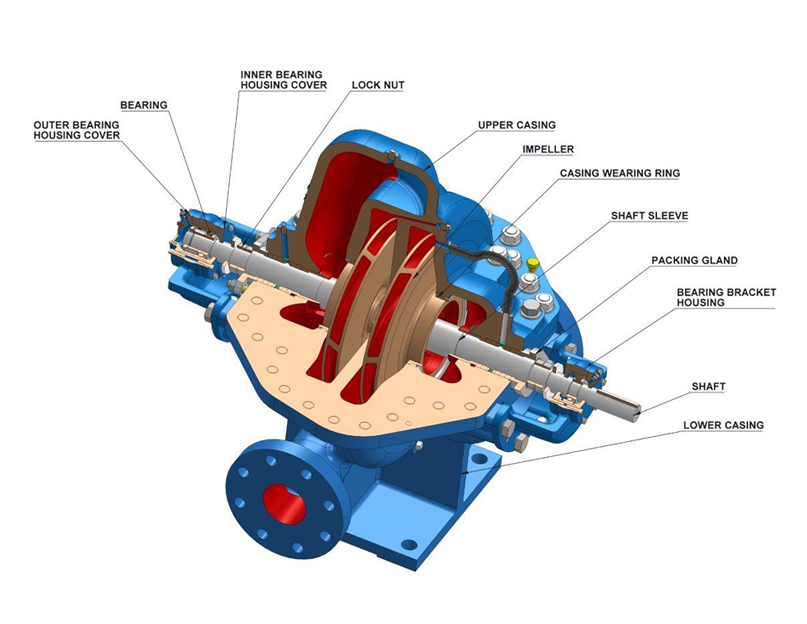

Construction & popular option:

Construction & Popular Option:

Horizontal Axially Split Casing, Single Stage, double suction with heavy duty shaft.

Horizontal Axially Split Casing, Single Stage, double suction with heavy duty shaft. Two Stage / double volute for high head pumps.

Two Stage / double volute for high head pumps. Rotating assembly can be taken out for easy inspection and maintenance by removing only upper casing half, without disturbing pump's alignment, suction and discharge pipe.

Rotating assembly can be taken out for easy inspection and maintenance by removing only upper casing half, without disturbing pump's alignment, suction and discharge pipe. Modular component designs for maximum interchangeability – less spare's inventory.

Modular component designs for maximum interchangeability – less spare's inventory. Replaceable wearing rings are provided with anti-rotation arrangement.

Replaceable wearing rings are provided with anti-rotation arrangement. Replaceable shaft sleeves.

Replaceable shaft sleeves. Sump model / CFD / Seismic analysis.

Sump model / CFD / Seismic analysis. For special services casing / impellers with 350 BHN hardness can be given.

For special services casing / impellers with 350 BHN hardness can be given. Available in horizontal / vertical shaft construction.

Available in horizontal / vertical shaft construction. Packing Gland / Mechanical Seal.

Packing Gland / Mechanical Seal. Available in clockwise / counter clockwise rotation.

Available in clockwise / counter clockwise rotation. For Low Life Cycle cost configuration we offer Pump with Mech. Seal, efficiency coating and features to minimize down time during maintenance.

For Low Life Cycle cost configuration we offer Pump with Mech. Seal, efficiency coating and features to minimize down time during maintenance. Can operate with motors at 50 Hz / 60 Hz.

Can operate with motors at 50 Hz / 60 Hz.

Material Of Construction For Components:

GENRAL INFORMATION for MATERIAL OF CONSTRUCTION

| Part description | Material of Construction | |||||

| Casing / Bowl | Cast Iron / Ni. CI./Cast Steel / Stainless Steel / Duplex SS / Super Duplex SS/ Ni.-Resist / ---- | |||||

| Impeller | Cast Iron / Bronze / Cast Steel / Stainless Steel / Duplex SS / Super Duplex SS/ Ni.-Resist ---- | |||||

| Shaft | Carbon Steel / Stainless Steel / Duplex SS / Super Duplex SS ---- | |||||

| Wearing Ring | Cast Iron / Bronze / Cast Steel / Stainless Steel / Duplex SS / Super Duplex SS/ Ni.-Resist ---- | |||||

| Shaft Sleeve | Carbon Steel / Stainless Steel / Duplex SS / Super Duplex SS / ---- | |||||

| Bush Bearing | Bronze / Cutless Rubber / Thordon / Feroform / Green Tweed / ---- | |||||

| Material standards & grades | ||||||

| MOC | Indian | U.S. | DIN | British | ||

| Cast Iron | IS 210, Gr. FG 260 | ASTM A48, CL. 35 or 40 | 1691 GG 25 | BS EN 1561-GJL 250 | ||

| Cast Iron with Ni. | Normally gives 1.5% Ni. -------------------------------- Other percentage can give if desired ---------- | |||||

| Bronze | IS 318, Gr. LTB 2 | ASTM B62, B145 Alloy4A | CuSn5ZnPb | BS EN 1982-CC491K | ||

| ASTM B584 – C83600 | BS1400 LG2-C | |||||

| Phosphor Bronze | IS 28, Gr. 1 | |||||

| Aluminum Bronze | IS 305, Gr. AB1 | ASTM B 148 (9A) | UNS No. C95200 | |||

| Carbon Steel (Castings) | IS 1030, Gr. 230-450W | ASTM A216, Gr. WCB | ||||

| Stainless Steel (Castings) | IS 3444, Gr. 10 | ASTM A743, Gr. CA15 | 1.4106(X12Cr14) | |||

| IS 3444, Gr. 24 | ASTM A743, Gr. CA6NM | 1.4313(X3CrNiMo13-4) | 425 C 11 | |||

| IS 3444, Gr. 1 | ASTM A743, Gr. CF8 | |||||

| IS 3444, Gr. 1 | ASTM A351, Gr. CF8 | 1.4308 | EN 10213-4 1.4308 | |||

| IS 3444, Gr. 4 | ASTM A743, Gr. CF8M | |||||

| IS 3444, Gr. 4 | ASTM A351, Gr. CF8M | 1.4408 | EN 10213-4 1.4408 | |||

| IS 3444, Gr. 15 | ASTM A 743, Gr. CF3 | |||||

| IS 3444, Gr. 15 | ASTM A 351, Gr. CF3 | 1.4309 | EN 10213-4 1.4309 | |||

| IS 3444, Gr. 16 | ASTM A743, Gr. CF3M | |||||

| IS 3444, Gr. 16 | ASTM A351, Gr. CF3M | 1.4409 | EN 10213-4 1.4409 | |||

| Duplex SS & Super Duplex. Casting) | ASTM A890, Gr. 1B UNS No. J93372 CD4MCuN | |||||

| ASTM A890, Gr. 1C UNS No. J93373 CD3MCuN | ||||||

| ASTM A890, Gr. 2A UNS No. J93345 CE8MN | ||||||

| ASTM A890, Gr. 3A UNS No. J93371 CD6MN | ||||||

| ASTM A890, Gr. 4A UNS No. J92205 CD3MN | ||||||

| ASTM A890, Gr. 5A UNS No. J93404 CE3MN | ||||||

| Carbon Steel (Bars) | IS 1570(P-III), Gr. 40C8 | ASTM A107, Gr. 1040 | BS 970(En-8)/080M40 | |||

| IS 1570(P-III), Gr. 55C8 | AISI 1055 | CK55 | BS 970(En-9)/070M55 | |||

| Stainless Steel (Bars) | IS 1570(P-V), Gr.X12Cr12 | ASTM A276, Type 410 | 1.4006 (X10Cr13) | 410 S21 | ||

| IS 1570(P-V), Gr.X15Cr16Ni2 | ASTM A276, Type 431 | 1.4057 (X20CrNi17) | ||||

| ASTM A276, Type 304 | 1.4301 (X5CrNi18 10) | 304 S15 | ||||

| IS 1570(P-V), Gr.X04Cr17Ni12Mo2 | ASTM A276, Type 316 | 1.4401 (X5CrNiMo17122) | 316 S31 | |||

| IS 1570(P-V),Gr.X02Cr17Ni12Mo2 | ASTM A276, Type 316L | 1.4404 (X2CrNiMo17122) | 316 S11 | |||

| Duplex SS (Bars) | ASTM A276, UNS S31803 | 1.4462 (X2CrNiMoN22 5) | ||||

| ASTM A276, UNS S32760 | 1.4501(X3CrNiMoN25 7) | |||||

| Steel (Plates) | IS: 2062 (Fe 410 WA) | ASTM A283, Gr. D | 1700 Gr ST 4-2 Fab. Steel 4-4 | |||

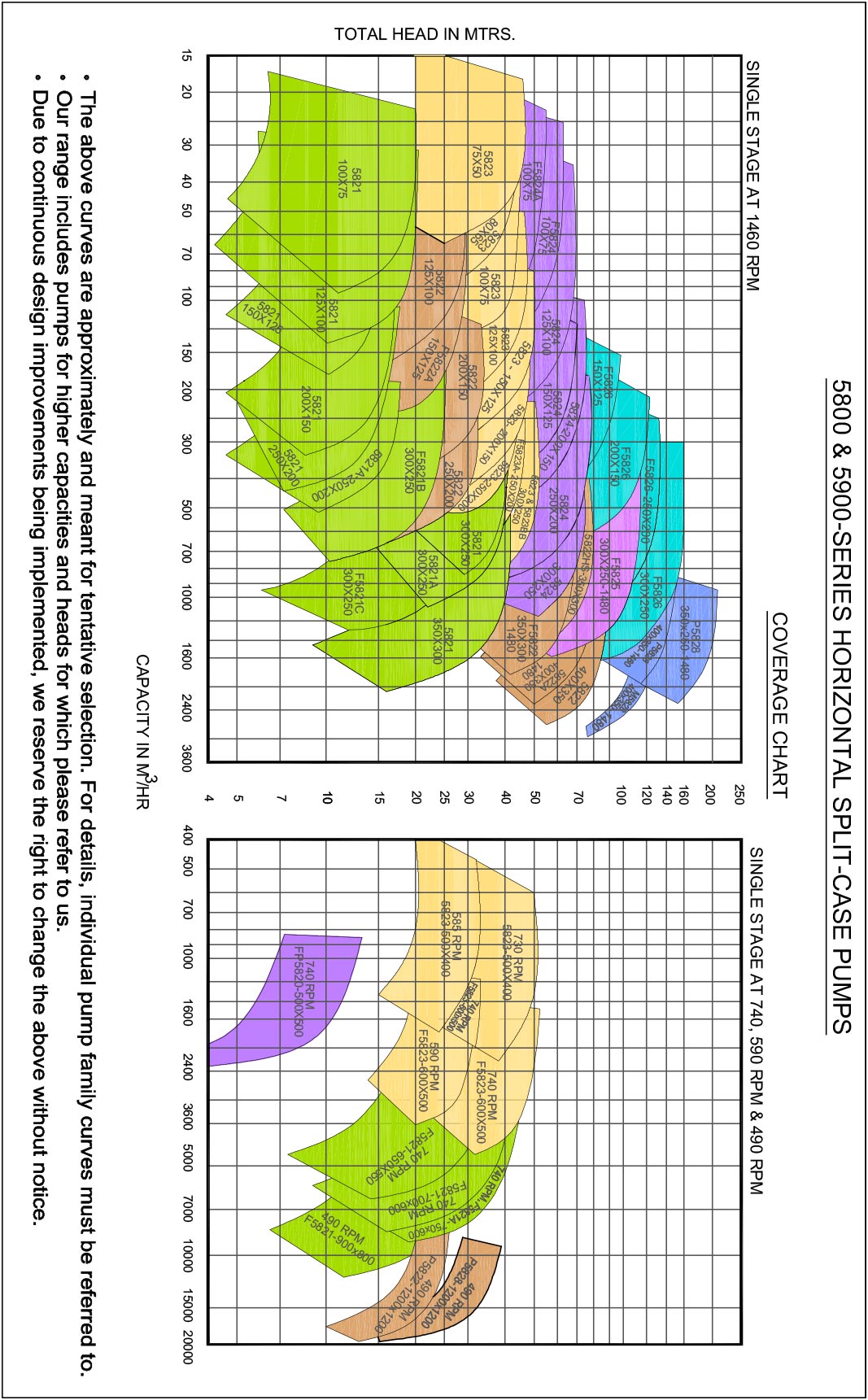

Coverage Chart

Notes:

- The above curves are approximate and meant for tentative selection. For details, individual pump family curves must be referred to.

Our ranges also includes pumps for higher capacities and heads for which please refer to us. Due to continuous design improvements being implemented. We reserve the right to change the above without notice.

-

Product Catalogue

Horizontal Split Casing Pumps

Horizontal Split Casing Pumps

-

O & M Manual

Horizontal Split Casing Pumps

Horizontal Split Casing Pumps